System wizyjny FH

Szybsza praca maszyn — kamery do każdego zastosowania

Ta gama produktów łączy zalety inteligentnej kamery i zaawansowanego systemu wizyjnego w ramach jednej platformy. Unikatowa wyrazistość obrazu osiągnięta dzięki zastosowaniu inteligentnej kamery upraszcza proces konfiguracji, przyspiesza instalację i zapewnia lepsze parametry optyczne.

- Wysokiej jakości komponenty zapewniające wyjątkową wydajność, spełniającą najsurowsze wymagania

- Inteligentne algorytmy i narzędzia wizyjne zapewniające solidność i niezawodność w każdym zastosowaniu — i przy każdej szybkości

- Nowoczesna gama kamer umożliwiająca wybór sprzętu najbardziej odpowiedniego do danego zastosowania — najlepsze rezultaty w najlepszej cenie

- Zdolność sztucznej inteligencji do naśladowania ludzkiego zmysłu wzroku i doświadczenia

- Łatwa integracja z oprogramowaniem dla elastycznej automatyzacji

- Przetwarzanie obrazu w pełnym spektrum barw (16 mln kolorów)*

- Komunikacja EtherNet/IP i TCP/IP*

Jak możemy Ci pomóc?

W razie pytań lub chęci przesłania prośby o wycenę skontaktuj się z nami lub wyślij zlecenie.

Proszę o kontakt System wizyjny FH

Dziękujemy za wysłanie zapytania. Otrzymasz od nas odpowiedź tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

DownloadOferta dla System wizyjny FH

Poniżej możecie Państwo wysłać zapytanie cenowe dotyczące naszych produktów. Prosimy wypełnić wszystkie pola oznaczone *. Twoje dane osobowe będą oczywiście traktowane jako poufne.

Dziękujemy za zlecenie wyceny. Dostarczymy Ci niezbędnych informacji tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

DownloadCechy

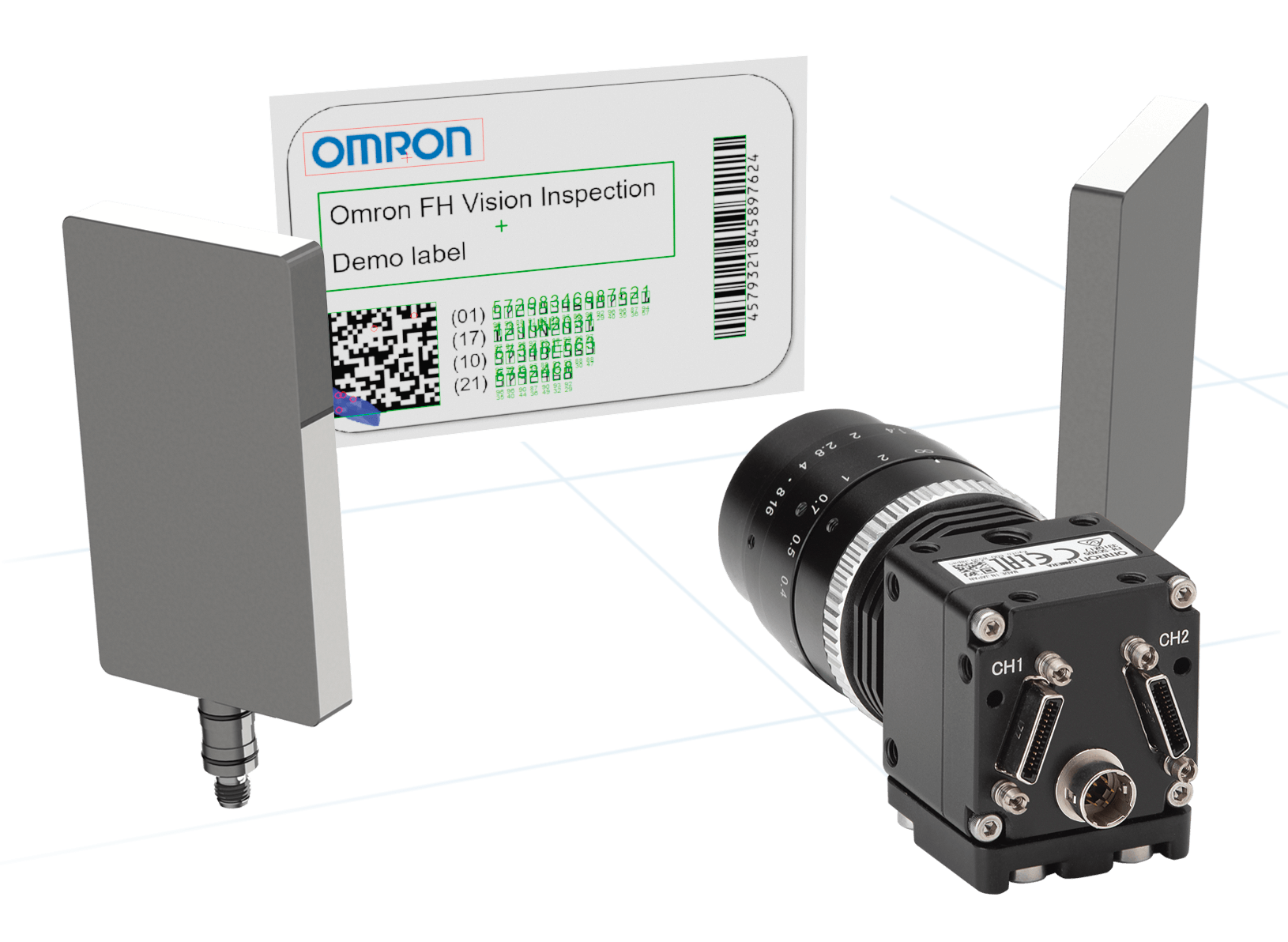

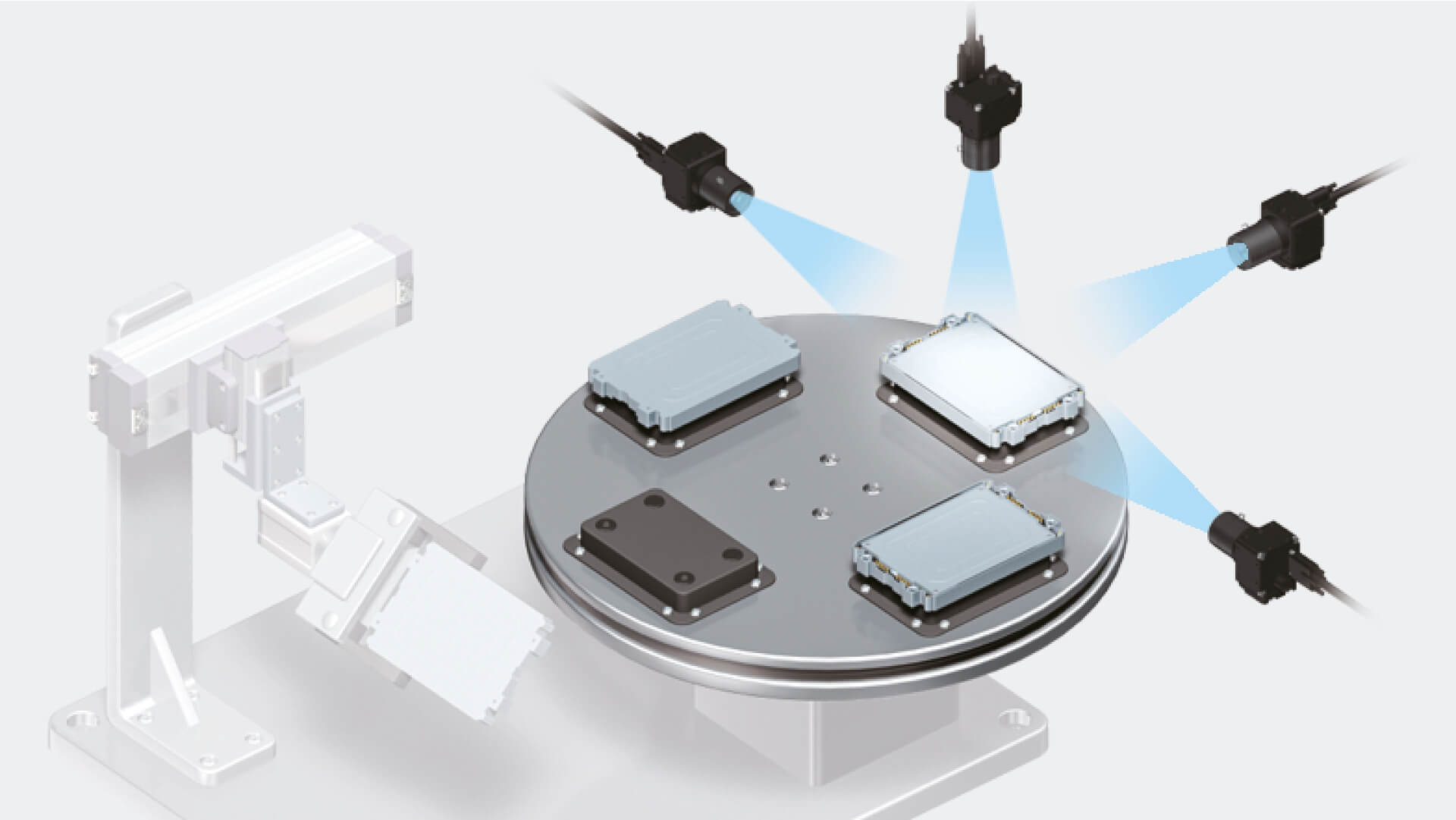

Pełna gama kamer o dużej prędkości / wysokiej rozdzielczości

Kamery FH są przeznaczone do wszystkich typów zadań związanych z kontrolą obiektów, sterowaniem położeniem/kierunkiem, odczytywaniem kodów i pomiarami. System złożony z kompaktowej kamery i sterownika można łatwo zintegrować z praktycznie każdą maszyną i każdym robotem. Ponadto oferuje on unikalną możliwość przyspieszenia i zwiększenia dokładności pracy, dzięki czemu zapewnia liczne korzyści, w tym podniesienie wydajności i obniżenie kosztów.

Rozszerzony zakres wykrywania dzięki kamerom z polaryzacją i SWIR

Firma OMRON znacząco rozszerzyła możliwości wykrywania obrazu poprzez rozbudowę portfolio kamer. Teraz dostępne są dwa warianty rozdzielczości w przypadku kamer SWIR oraz dwie kamery o spolaryzowanej rozdzielczości. Te dodatki znacznie zwiększają zasięg wykrywania i wszechstronność serii FH

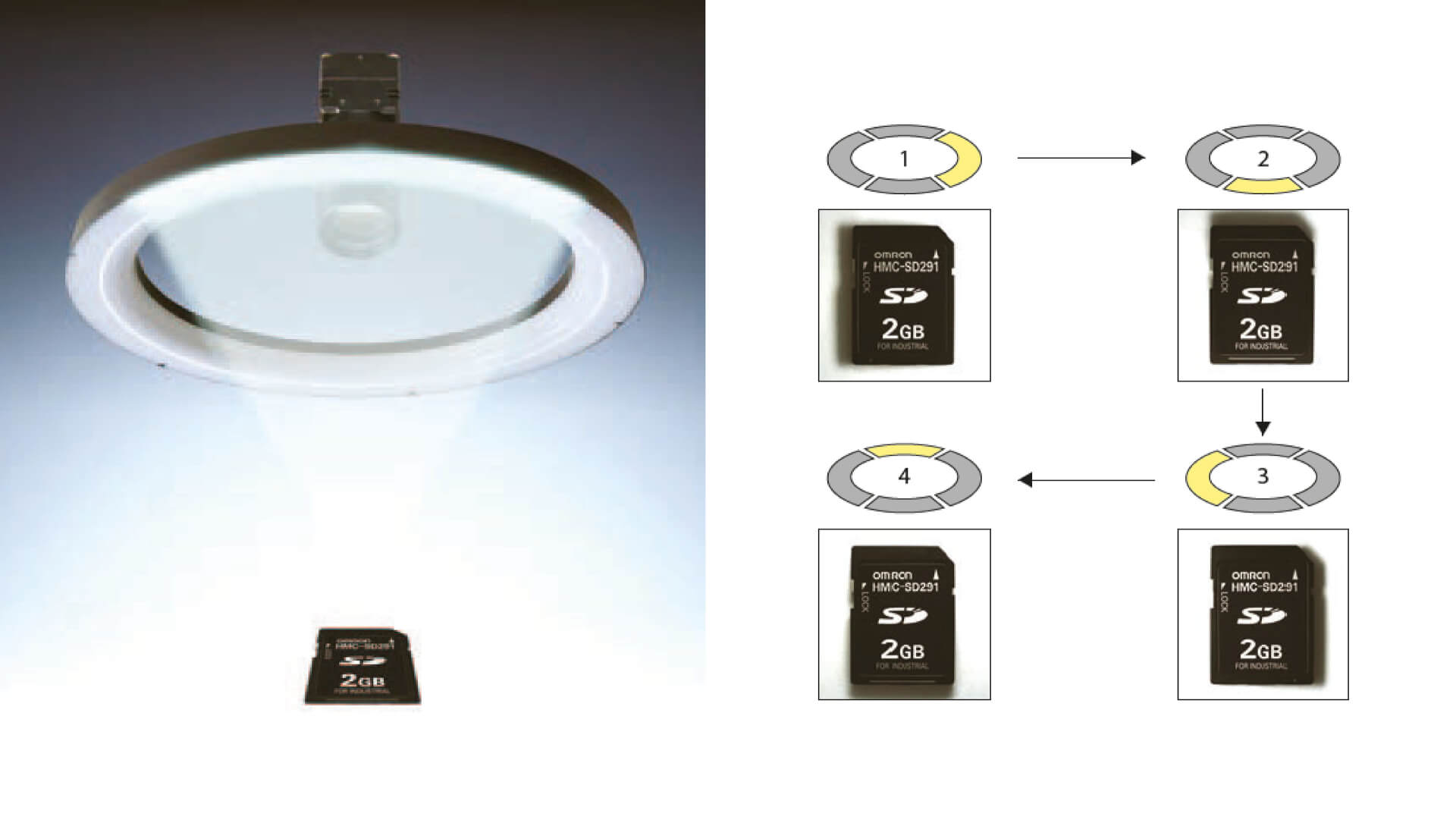

Zaawansowane obrazowanie metodą stereoskopii fotometrycznej

Oświetlenie fotostereoskopowe FH można stosować w kamerach o standardowej lub wysokiej rozdzielczości do 20,4 megapiksela, na przykład do wykrywania wgnieceń i uszkodzeń powierzchni z dużą dokładnością. Po kolei zapalane są cztery światła, co pozwala analizować różnice w jasności. Drukowane znaki o niewielkich różnicach w jasności są wyodrębniane jako tekstura nawet w różnych kierunkach oświetlenia, a wgniecenia o dużej zmienności w jasności są wyodrębniane jako kształt

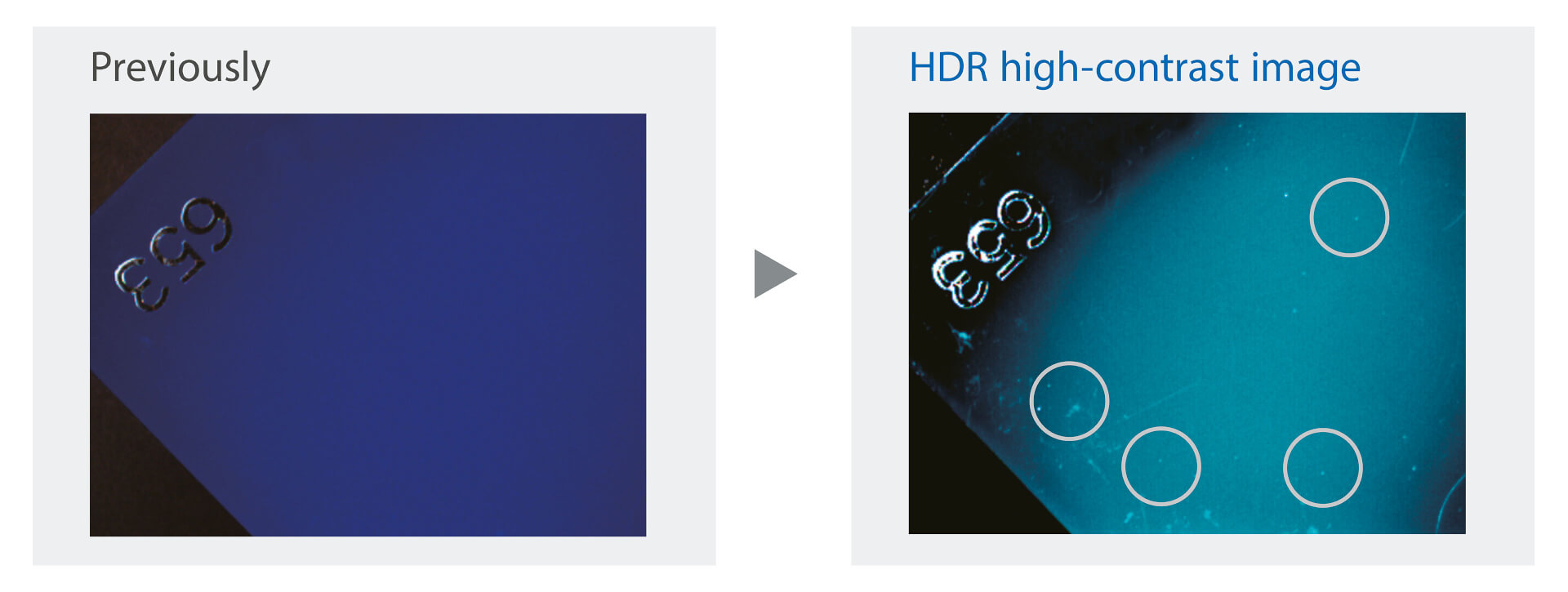

Obrazowanie HDR

HDR pomaga tworzyć zoptymalizowane obrazy w zmiennych warunkach otoczenia. Po określeniu optymalnego obszaru, który ma zostać zarejestrowany na obrazie, kamera z serii FH automatycznie dostosowuje czas naświetlania podczas rejestrowania obrazów i ich łączenia.

Kompleksowe narzędzia wizyjne oparte na regułach

Oparte na regułach narzędzia wizyjne FH firmy OMRON znajdują się w czołówce branży automatyki przemysłowej, dostarczając najnowocześniejsze rozwiązania do kontroli jakości, inspekcji i optymalizacji procesów. Dzięki wykorzystaniu zaawansowanych algorytmów i precyzyjnej technologii obrazowania te narzędzia wykonują złożone zadania z wyjątkową dokładnością i niezawodnością. Zaprojektowane z myślą o łatwości obsługi narzędzia wizyjne firmy OMRON zapewniają bezproblemową integrację z istniejącymi systemami, a czas ich konfiguracji jest minimalny.

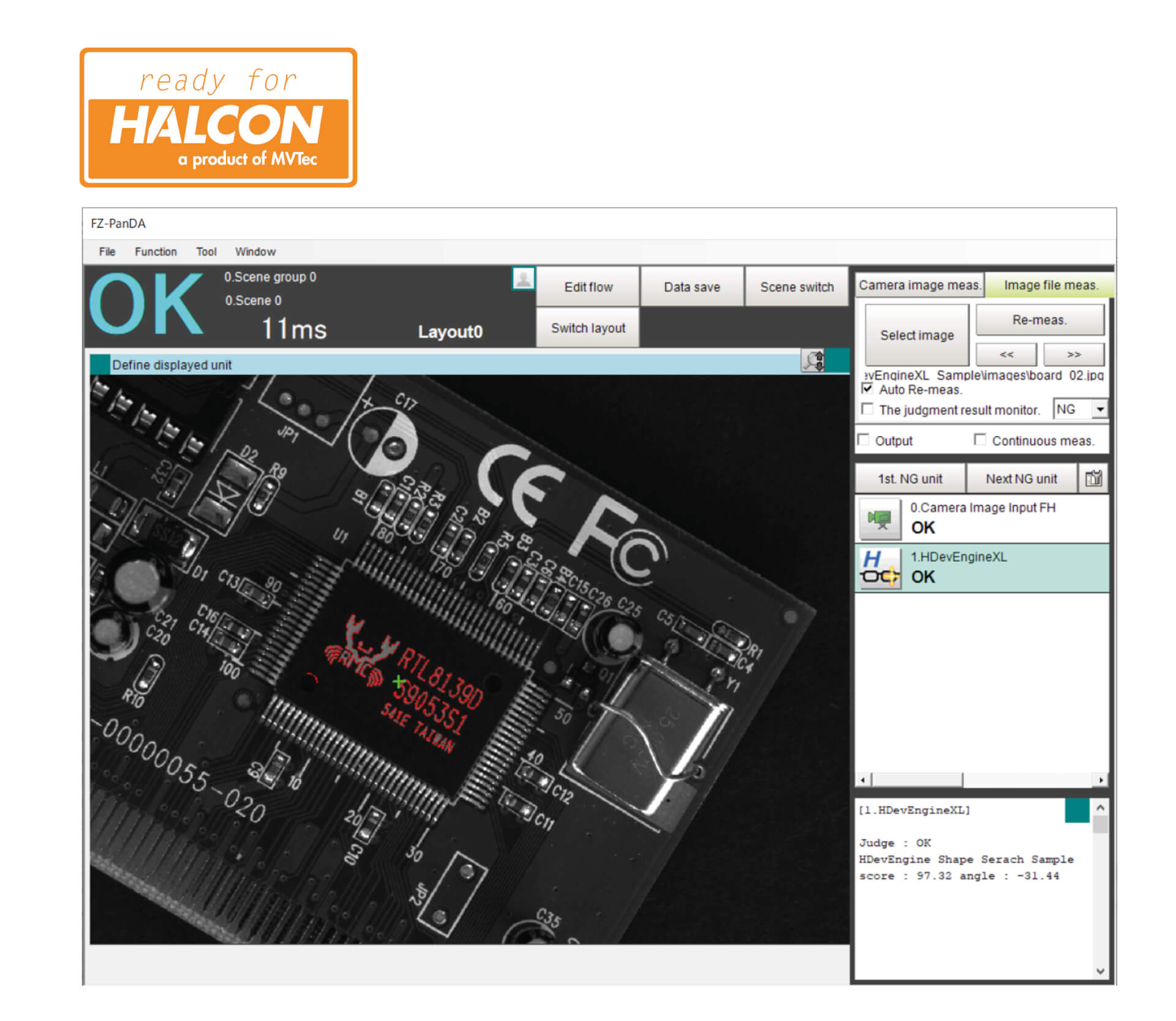

Otwarta seria FH

Oprócz opatentowanych algorytmów wizyjnych firmy OMRON sterownik wizyjny FH jest zgodny z algorytmami wizyjnymi opracowanymi przy użyciu oprogramowania Halcon HDevoc firmy MVTec. Elastyczność ta pozwala producentom wybrać najlepsze podejście algorytmiczne do specyficznych wymagań zastosowania, zapewniając optymalną wydajność w ich rozwiązaniach wizyjnych

Elastyczna sztuczna inteligencja na brzegu sieci

Uwolnij pełny potencjał automatyzacji opartej na sztucznej inteligencji dzięki sterownikowi wizyjnemu FH, który jest wyposażony w starannie dobraną gamę procesorów Intel, a także udoskonalony poprzez zestaw narzędzi OpenVINO. Ta potężna synergia umożliwia wdrażanie zaawansowanych modeli SI bezpośrednio do sterownika wizyjnego FH, zapewniając niezrównane przetwarzanie i analizę obrazu w czasie rzeczywistym. Zestaw narzędzi OpenVINO optymalizuje wydajność, umożliwiając płynne wykonywanie wnioskowania opartego na głębokim uczeniu przy minimalnych opóźnieniach. Przekłada się to na szybsze i dokładniejsze podejmowanie decyzji, wyższą wydajność operacyjną oraz doskonałą kontrolę jakości. Udoskonal swoje procesy automatyzacji dzięki sterownikowi wizyjnemu FH firmy OMRON, który łączy najnowocześniejszą sztuczną inteligencję z zaawansowanymi możliwościami obliczeniowymi firmy Intel dzięki przełomowemu zestawowi narzędzi OpenVINO.

Wykrywanie defektów przy użyciu sztucznej inteligencji

Dzięki wykorzystaniu zaawansowanych algorytmów uczenia maszynowego sterownik FH umożliwia producentom osiąganie niezrównanej dokładności i wydajności w identyfikacji oraz kategoryzowaniu wad w różnych procesach produkcyjnych. Obsługuje to kontrolę pod kątem wad wspomaganą przez sztuczną inteligencję, w tym wykrywanie anomalii, klasyfikację i zadania segmentacji.

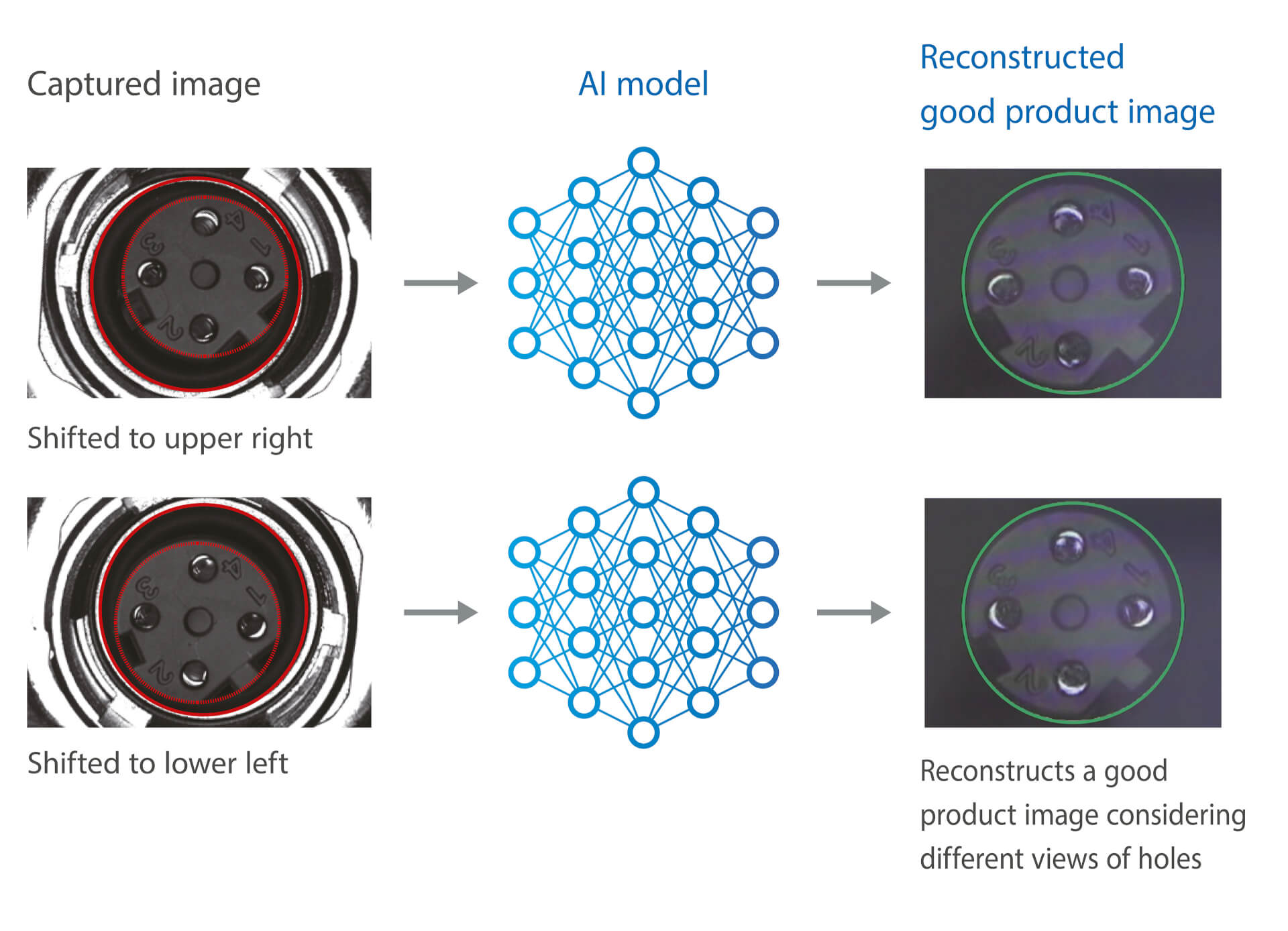

Dokładne dopasowywanie dzięki sztucznej inteligencji

Funkcja dokładnego dokładne dopasowywanie z pomocą sztucznej inteligencji identyfikuje cechy, których nie powinny mieć dobre produktu, jako wady. Sztuczna inteligencja uczy się na podstawie obrazów różnych wariantów dobrych produktów i generuje model SI. Za każdym razem, gdy przeprowadzana jest kontrola, sztuczna inteligencja rekonstruuje model, który uznaje się za dobry produkt. Następnie wyodrębnia różnicę między zrekonstruowanym obrazem dobrego produktu a obrazem zarejestrowanym w celu zidentyfikowania wady, co zmniejsza nadmierną detekcję wad.

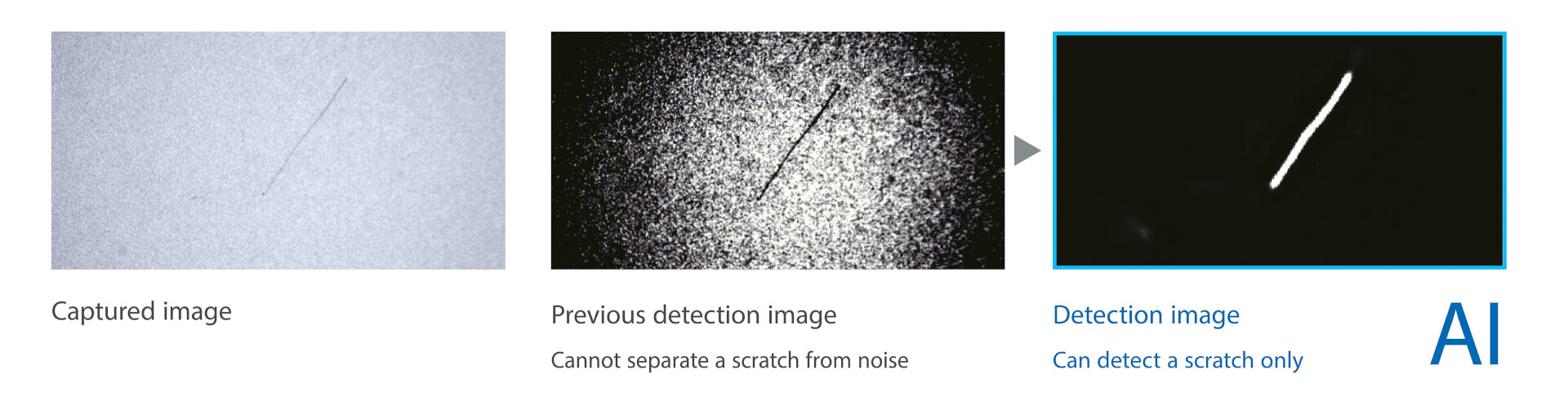

Wykrywanie zarysowań z pomocą sztucznej inteligencji

Najnowsze funkcje systemu wizyjnego FH obejmują filtr obrazu oparty na sztucznej inteligencji, który odtwarza technikę wykorzystywaną przez wykwalifikowanych inspektorów do identyfikacji wad na dowolnym tle produktu. Zarysowania i skazy, które były niegdyś trudne do uchwycenia, można teraz zidentyfikować nawet bez użycia próbek lub regulacji

Zastosowania

Gotowy system wizyjny zgodny z normami 21 CFR Part 11 i GAMP

System FH Vision można zmodernizować zgodnie z wymaganiami norm 21 CFR Part 11 i GAMP, co umożliwia branży medycznej, farmaceutycznej i producentom urządzeń medycznych montowanie systemów wizyjnych na swoich liniach produkcyjnych w celu zapewnienia zgodności z tymi normami.

Funkcje oprogramowania

- Raport tworzenia dzienników inspekcji

- Przeglądarka dzienników inspekcji

- Zwiększone bezpieczeństwo haseł

- Zaszyfrowane pliki

- Kontrola dostępu użytkowników

- Możliwość logowania jednorazowego

- Integracja HMI

Cyfrowe dekodowanie znaków wodnych Digimarc

Niezrównane możliwości dekodowania na opakowaniach cylindrycznych i elastycznych

Kontrola wyglądu ogniw akumulatora

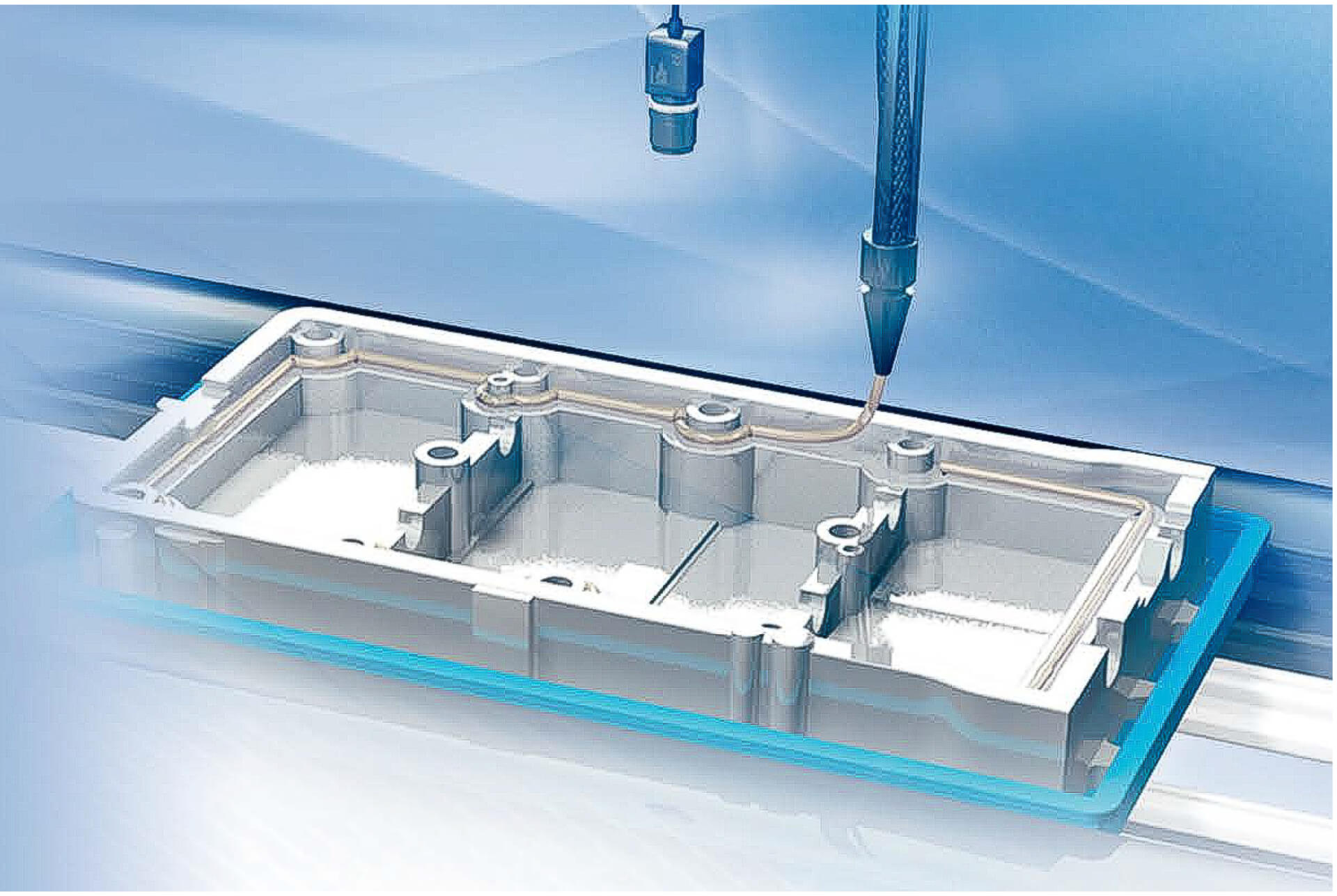

Kontrola warstwy kleju

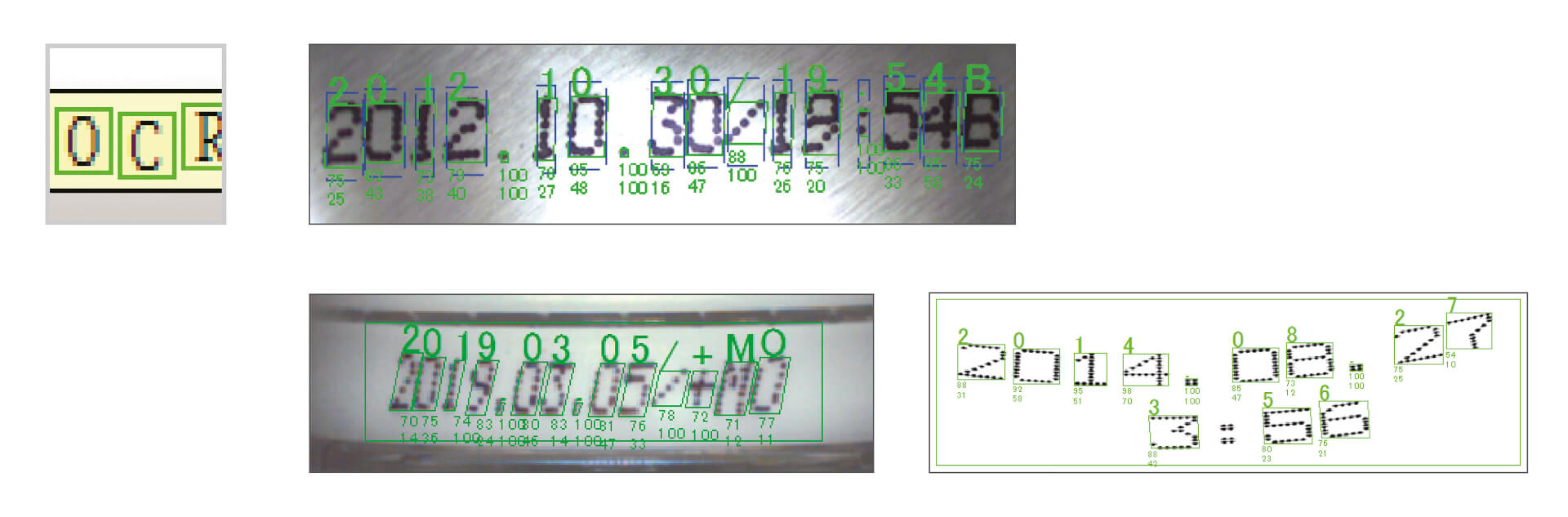

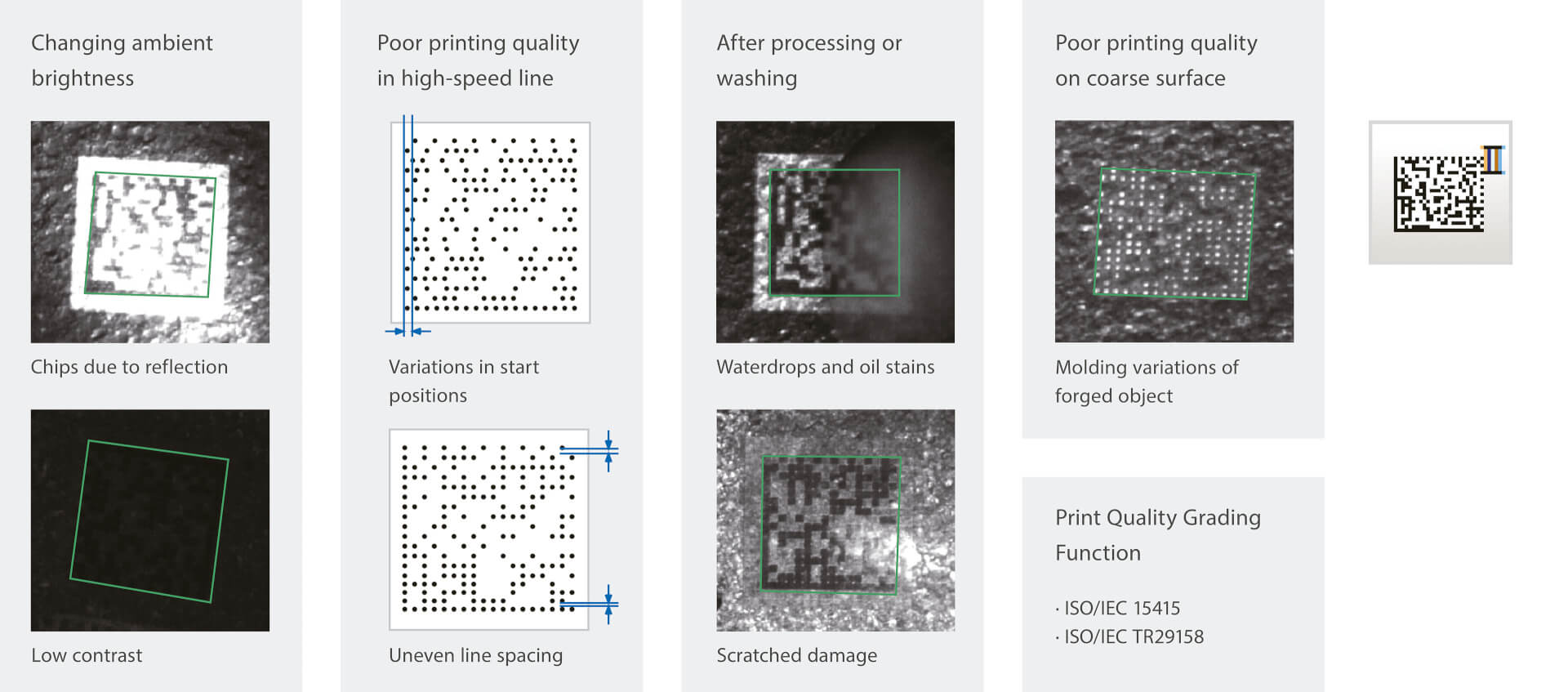

Niezawodny odczyt trudnych do odczytania znaków

Lens Selector

Filmy

-

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Modele i specyfikacja

| Produkt | Performance | Processor family | Operating system | Memory | AI Scratch detection filter | AI FineMatching | Number of cameras | Integrated monitor | Communication port(s) | Output type | Application | Opis | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (ECC) | No | No | 4 | No | EtherCAT Slave, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 2 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH-Lite controller, standard grade, box type, 2 camera, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 4 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Counting, Defect inspection, Measurement inspection, OCR / OCV | FH-Lite controller, standard grade, box type, 4 camera, , W10 IoT Enterprise LTSC 2019 64bit |

|

Nowy system wizyjny z innowacyjną detekcją defektów SI dla urządzeń z serii FH

Mamy niemal nieskończoną liczbę kombinacji, aby spełnić wymagania każdych warunków produkcyjnych.

Chcesz wiedzieć więcej?

Proszę o kontakt System wizyjny FH

Dziękujemy za wysłanie zapytania. Otrzymasz od nas odpowiedź tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

DownloadOferta dla System wizyjny FH

Poniżej możecie Państwo wysłać zapytanie cenowe dotyczące naszych produktów. Prosimy wypełnić wszystkie pola oznaczone *. Twoje dane osobowe będą oczywiście traktowane jako poufne.

Dziękujemy za zlecenie wyceny. Dostarczymy Ci niezbędnych informacji tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

DownloadPliki do pobrania

Teraz zaloguj się lub zarejestruj się, aby zobaczyć zawartość

Teraz zaloguj się lub zarejestruj się, aby zobaczyć zawartość

Teraz zaloguj się lub zarejestruj się, aby zobaczyć zawartość

Powiązane produkty

Jak możemy Ci pomóc?

W razie pytań lub chęci przesłania prośby o wycenę skontaktuj się z nami lub wyślij zlecenie.

Proszę o kontakt System wizyjny FH

Dziękujemy za wysłanie zapytania. Otrzymasz od nas odpowiedź tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

DownloadOferta dla System wizyjny FH

Poniżej możecie Państwo wysłać zapytanie cenowe dotyczące naszych produktów. Prosimy wypełnić wszystkie pola oznaczone *. Twoje dane osobowe będą oczywiście traktowane jako poufne.

Dziękujemy za zlecenie wyceny. Dostarczymy Ci niezbędnych informacji tak szybko, jak to tylko będzie możliwe.

Problem techniczny. Akcja nie została wykonana. Przepraszamy - spróbuj ponownie.

Download